Color mark sensr

Color mark sensor:

They are designed and manufactured for detecting color codes on packaging films (made of PVC, OPP, BOPP, wax paper, paper, etc.) with a transparency level comparable to that of a mirror.

The working principle of these sensors is based on emitting white light and receiving the light reflected from the packaging paper.

Note:

Using a switch, the normally open (NO) and normally closed (NC) modes can be selected.

Sensitivity to different colors can be adjusted using the potentiometer on the sensor.

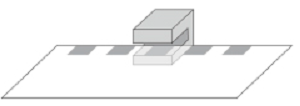

Fork type color mark sensor:

These sensors are used for transparent packaging films such as cellophane, nylon, etc. In this type, a visible light transmitter and receiver are positioned facing each other. When a color code on the packaging passes between them, the light beam is interrupted, causing a change in the sensor's output state.